The full-automatic horizontal oxidation electrophoresis production line of Feixian No.2 Factory of Kemet Company was put into operation to increase benefits.

Release time:

2016-06-24

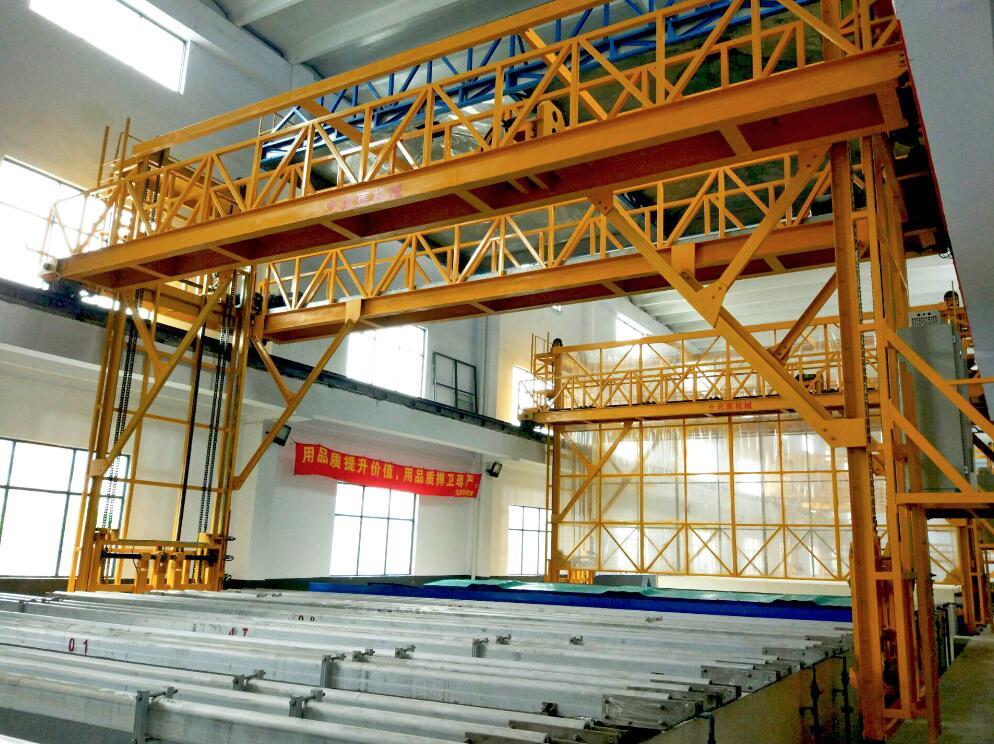

In early June, the trial production of the fully automatic horizontal oxidation electrophoresis production line in Feixian No.2 Plant of Kemet Company was successful and put into use to increase benefits, which also indicates that the product supply cycle of the Kemet oxidation electrophoresis production line will be effectively shortened. the production process has entered a new stage of automatic production. The fully automatic horizontal oxidation electrophoresis production line introduced by Kemet this time adopts Korean cutting-edge technology, with an investment of more than 20 million yuan, a plant construction area of nearly 10000 square meters, and an annual production capacity of 20000 tons. The production line will be the industry's advanced technology, automatic control perfect combination, the whole process fully reflects the ERP data information and industrialization of good integration, all process, control, recording parameters intelligent input, can achieve the whole process, all-weather, fully automatic control. At the same time, the production line has the advantages of high production efficiency, stable product quality and reduced labor costs. It runs through advanced resource utilization and environmental protection concepts. The energy consumption of electricity, water and wastewater treatment has been reduced by nearly half, and the energy saving and environmental protection effect is remarkable. The use of the full-automatic horizontal oxidation electrophoresis production line in the second plant of Feixian County of Kemet Company will effectively improve product quality, allow customers and consumers to reduce product waiting time, and achieve quality in shortening product production cycle and supply cycle. Leap.

The commissioning of the full-automatic horizontal oxidation electrophoresis production line in the second plant of Feixian County of Kemet Company will effectively improve product quality, allow customers and consumers to reduce product waiting time, and shorten product production cycle and supply Cycle and other aspects will achieve a qualitative leap.

Contact Information

Customer Service Tel: +86-539-7177878

Mailbox: kemet@sdkemet.com

Zip Code: 273400

Address: Linyi City, Shandong Province

Copyright©2023 Kemet New Materials Technology Co., Ltd. All Rights Reserved